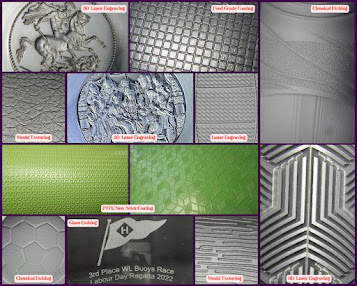

Laser Marking: Unleashing Precision and Versatility

In the world of modern manufacturing and industrial processes, precision and versatility are often the keys to success. Laser marking has emerged as a transformative technology, offering unparalleled precision and versatility across various applications. In this article, we will explore the fascinating world of laser marking services, with a particular focus on laser printing on metals and its role in mold polishing. The Power of Laser Marking Services Laser marking services have gained immense popularity across industries due to their ability to create permanent, high-precision markings on a wide range of materials. The process involves using a focused laser beam to engrave, mark, or etch a surface, leaving behind a permanent, legible mark. Let's delve deeper into the world of laser marking and its diverse applications. Laser Printing on Metals: Durability Meets Precision Metal is a commonly used material in various industries, including automotive, aerospace, and electro...

.png)