Discover the Art of Sunmica Steel Plate Etching: A Creative Process

In the world of design and manufacturing, the marriage of

art and technology often leads to extraordinary innovations. Sunmica steel

plate etching is a prime example of this fusion, offering a unique and creative

approach to customizing stainless steel surfaces. In this blog post, we'll

delve into the fascinating world of Sunmica steel plate etching and explore how

it can transform ordinary stainless steel into works of art. Plus, we'll also

touch on the importance of finding the best-priced etching roller to make the

most of this creative process.

Sunmica Steel Plate

Etching: An Overview

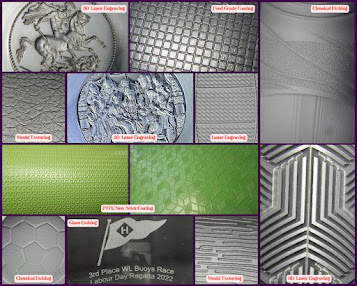

Sunmica

steel plate etching is a versatile and precise process that involves the

selective removal of material from a stainless steel surface using chemicals.

This process not only adds an artistic touch but also serves practical purposes

such as branding, labeling, and product identification.

The Creative

Potential

One of the most remarkable aspects of Sunmica steel plate

etching is its ability to transform a cold and industrial material like

stainless steel into a canvas for creativity. Designers and manufacturers can

use this process to add intricate patterns, logos, graphics, or even photographs

to stainless steel surfaces.

From architectural elements like elevator doors and wall

panels to intricate signage and nameplates, Sunmica steel plate etching offers

endless possibilities for enhancing aesthetics and conveying a brand's

identity. It allows for the creation of visually stunning and durable designs

that stand the test of time.

The Process of

Sunmica Steel Plate Etching

1.

Preparation: The process begins with the

preparation of a stainless steel plate. It is thoroughly cleaned and coated

with a photoresist material, which serves as a protective layer.

2.

Design Transfer: The desired design is then

transferred onto the photoresist layer using various techniques, such as

exposure to ultraviolet (UV) light through a mask or direct printing.

3.

Chemical Etching: The plate is submerged in a

chemical solution that selectively removes the unprotected areas of the

photoresist layer and the underlying stainless steel, creating the etched

design.

4.

Rinsing and Inspection: After the etching

process, the plate is thoroughly rinsed to remove any residual chemicals. The

resulting design is inspected for accuracy and quality.

5.

Finishing: Depending on the intended

application, the etched stainless steel plate may undergo additional processes

like polishing or coating to enhance its appearance and durability.

Sunmica Steel Plate

Etching in Practice

Architectural

Applications

Sunmica steel plate etching finds extensive use in

architectural design. Elevator doors, wall panels, and decorative features in

commercial and residential buildings benefit from the elegance and longevity

that etched stainless steel provides. The interplay of light and shadow on

etched surfaces can create stunning visual effects, adding depth and dimension

to spaces.

Branding and Signage

For businesses and brands looking to make a lasting

impression, etched stainless steel is a standout choice for signage and

branding. It exudes professionalism and sophistication while ensuring visibility

and recognition.

Product

Identification

Etched stainless steel plate

etching are used as strong, long-lasting identifying tags in production.

They are durable enough to survive adverse climatic conditions and offer vital

details about goods and their constituent parts, ensuring traceability and

quality control.

Finding the

Best-Priced Etching Roller

To maximize the benefits of Sunmica steel plate etching,

it's essential to have the right equipment and tools, including an etching

roller. This tool plays a critical role in ensuring the even application of the

photoresist layer and the precise transfer of designs onto stainless steel

plates.

When looking for an etching roller, consider factors like

durability, ease of use, and price. Finding an etching roller at

the best price doesn't mean compromising on quality. It means finding a

balance between cost and performance to ensure efficient and consistent results

in the etching process.

In conclusion, Sunmica steel plate etching is a creative

process that breathes life into stainless steel surfaces, turning them into

artistic expressions and functional elements. Whether you're an architect, a

business owner, or a manufacturer, this innovative technique offers a world of

possibilities for customization and design. And by choosing the right

equipment, such as an etching roller at the best price, you can embark on your

creative journey with confidence, knowing that your ideas will come to life

with precision and excellence.

Comments

Post a Comment